We, “Long Beach International Limited” a company founded in 1998, we have more than two decades of experience in the manufacturing of textiles. We specialize in the production of special textile /exclusively knitted, printed & dyed fabrics for the Toys, Footwear, Bag & Garment industries. We can also handle special purpose fiber Including synthetic fiber & polyester. In respect of garments, we are able to provide highly efficient one-stop services covering development, production management to shipping. Our products are shipped worldwide especially Europe, United States & Asia. Our reputation is widely recognized and quality & reliability of services deeply appreciated by our clients.

On the ground technical support in China is provided by our wholly-owned subsidiary company Chang Ti Textile (Dongguan) Co., Ltd, which is managed with the same standard of experience, skill & care.

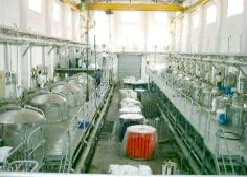

Production Process

The production is fully and vertically integrated with advanced and computerized machineries, and continuous trainings are provided to employees and advanced testing equipment is used as to ensure our product quality. Below is a diagram showing the major steps in the production procedure for

(i) fabric knitting from yarns; (ii) fabric bleaching and dyeing; (iii) fabric setting and finishing; and (iv) yarn bleaching and dyeing.

(i) Fabric Knitting from Yarns

Fabric can be knitted either from raw yarns or dyeing yarns. The decision made is dependent on customer's choice. To ensure the fabric produced is in the highest quality, all the knitting machinery are equipped with the devices which are able to detect the defects during the production processes. Any rectify measures can then be implemented immediately. The knitting machines are imported from Japan, Taiwan, Britain and Germany.

(ii) Fabric Bleaching and Dyeing

Fabric, whether those produced by us or those provided by customers to require for fabric processing service, has to be bleached in order to facilitate the dyeing process thereafter. Most of bleaching material and dyestuff, sourced from China, Britain, Germany, South Korea, Taiwan and France, have to be tested before they are put into dyeing process. Computerized dyeing machines were operated by experienced technicians, which can dye the fabric into the colour able to meet the customer's standard and any specific requirements.

(iii) Fabric Setting and Finishing

Fabric setting and finishing refer to the process that the texture, size and shape of the fabric are stabilized and fixed. Computerized machineries operated by skilful and experienced technicians process most of the steps.

(iv) Yarn Bleaching and Dyeing

Raw yarns needs to undergo a series of treatment and testing before dyeing for the color requested by the customers. And the dyeing yarns are suitable for the production of the knitting fabric and sweater. In order to keep the standard of the dyeing yarns, the most advanced and computerized machinery for yarn bleaching and dyeing were purchased.

Quality Assurance

As mentioned in our Mission, we are committed to serve you by our best quality products and services. And to fulfill your want is our first priority, the following means have been implemented as to ensure our quality of the product and service is the best before shipment :

Good on-job training is provided to the staff in the operation department and QA department.

Advanced computerized machinery with constant upgrading is used to ensure the production process meets the standard and produce the best quality products.

Calibration for the production machinery and quality assurance equipment is taken periodically.

Fully vertical production process enables us to have the strict control on the quality.

Raw yarns, dyestuff and chemicals are fully tested before utilization.

Yarns, which come from cones, have to be rewound and waxed before being put into production.

Systematic on-line quality checking is performed by professional technician during the production process.

The knitting machine is equipped with the devices to detect the defect which is made during knitting process.

The laboratory for colour matching and testing procedures in dyeing are fully computerized and operated by skilful staff to achieve the best quality.

Products need to be further examined based on our Quality Assurance Scheme before shipment.

Colour matching and testing procedures in dyeing labortories are fully computerized and conducted by skilful staff to

achieve best quality with uniformityFinished products have to be further examined according to company Quality Assurance Program before delivery